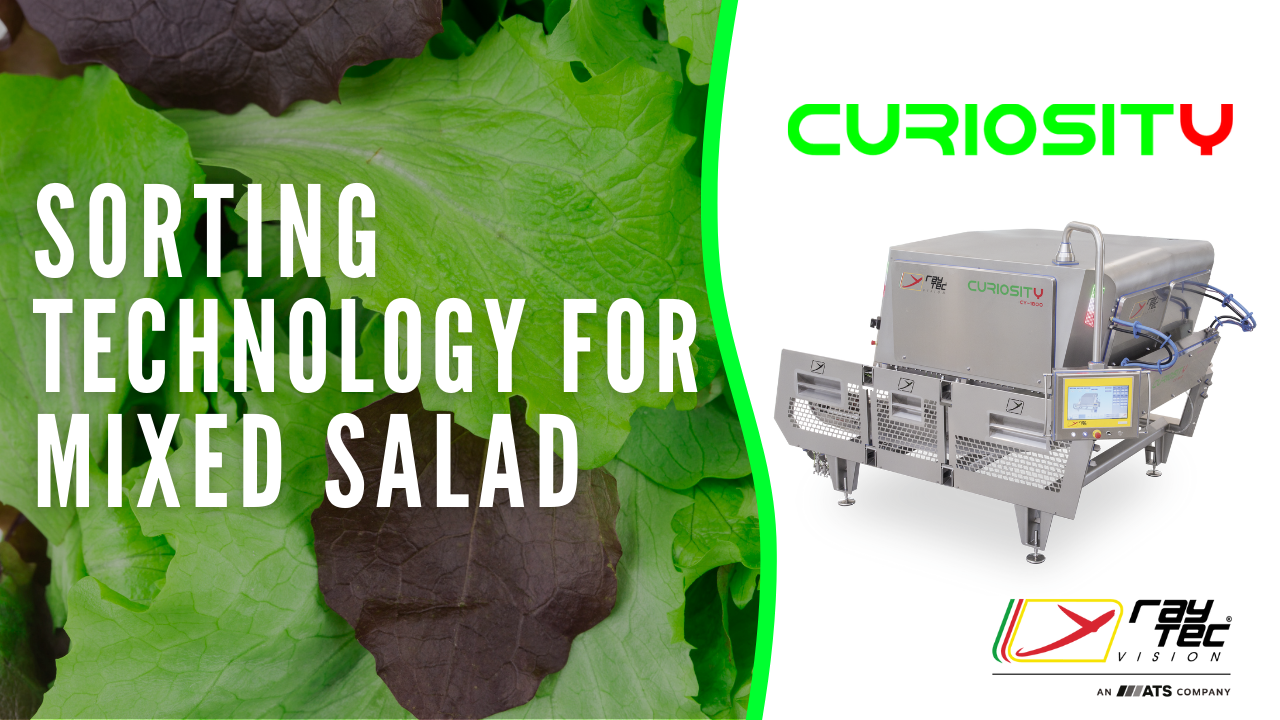

The first totally hygienic sorter

TECHNICAL INFORMATION

Technology:

• Pulsed LEDs with CCD cameras

Optical resolution:

• 0,3×0,3 mm

Vision:

• on belt – top view

Version:

• 2 WAY / 3 WAY

Models:

• CY-600 / CY-1200 / CY-1800

APPLICATIONS

Curiosity is the first optical sorting machine born to achieve the totally hygienic compliance according to the EHEDG guidelines.

This sorting machine combines innovation, essential design and latest vision technology, it perfectly meets the needs of safety and quality control, hygienic operation, easy and quick sanitation.

Guided by our powerful UNYCO software, Curiosity can detect all the defects you are looking to reject, while caring for the good part.

A vibratory shaker built in the machine conveys the product to a vertical chute ensuring a consistent trajectory.

Curiosity is available in 3 versions

CY-600:

600 mm vision width;

96 ejection valves.

CY-1200:

1200 mm vision width;

192 ejection valves.

CY-1800:

1800 mm vision width;

288 ejection valves.

Main characteristics

Inspired by the perfection of nature, Curiosity’s main frame is based on the same geometry adopted by the most performing industry.

The half-hexagonal shape guarantees at the same time the necessary resistance required by the load-bearing structure of the sorter and the possibility to reach every corner of the machine to sanitize in depth.

Curiosity is hollow-tube “free”! It is designed to make the sorting machine easy to clean to prevent the entry, survival & proliferation of microorganisms.

All surfaces are designed to avoid water pooling and they are self-draining. They are also easily cleanable with mechanical action during washing & sanitation procedures used to prevent biofilm formation.

The open frame shape allows any cable to be wired (air, water, logic signal, electric power), avoiding the presence of not-hygienic wire clumps.

Each cable can be easily sanitized without the use of tools.

• All utilities lines are separated (not bundled) to avoid soiling and/or allow sanitation.

• Seals and O-rings are designed to minimize the product contact.

• The Curiosity has the IP68 waterproof grade.

Even the standard lamp alarm has been replaced to avoid any unnecessary element around the machine. In its place 4 light displays are located in each corner of the sorter, to ensure clear and immediate identification of any alarm message.

Even the standard lamp alarm has been replaced to avoid any unnecessary element around the machine. In its place 4 light displays are located in each corner of the sorter, to ensure clear and immediate identification of any alarm message.

A smart frame design allows disassembly of the sorting belt in no more than 5 minutes, WITHOUT THE USE OF ANY TOOL.

All components in direct contact with the product are easily removable with no tools and can be sanitized by a COP procedure.

Other components or surfaces will be easily accessible for brush and direct sanitization “on board”. Everything is designed to help the user to achieve the highest level of hygiene on a daily basis.

The new motorized pulley replaces the traditional moto & gearbox drive system, bringing a few considerable benefits:

• Removal of all carters for an easy and deep sanitation.

• More balance weight distribution.

• No more bearings to be lubricated.

Curiosity is the result of a new design, especially conceived to comply all the EHEDG guidelines. This leads to a radical reduction of bacteria contamination and to a brand-new ease in washing that consent to save time and water.

Traditional plastic clamps are the nightmare of food safety. The only way to avoid contamination is to not using them: that’s why we developed a support that can block the cables with a simple interweaving.

The most updated sanitary procedures require frequent changings and sterilizations of the sorting belt. Curiosity adopted a dedicated assembly that enables a less than 5 minutes, hand-only change.

Raytec has developed a multispectral technology of 10 frequencies: Decaray. Curiosity pairs it with UNYCO software, in order to process many different application typologies.

Curiosity is available both with one or two groups of pneumatic expulsion , both with 6 mm step valves. Our Smart-Jet board takes full control of the rejection systems, both electric and pneumatic. Use less time for your out of production tests!

Conceived alongside the EHEDG norms, Curiosity easily reaches the IP68 electric protection for the machine, and the IP68 for the cabinet.

An ethernet connection is available for remote control.

The Raymote safe connection is available for internet access.

The Raymote Firewall allows to connect automatically to Raytec’s control systems, guaranteeing an efficient, continuous and safe assistance: Raymote has been designed to avoid external hacks.

The machine detects statistical data on rejected products for quality analysis of the selected raw material.

The area inside cabinet is provided with a conditioning system that opens up the possibility to operate from 4 °C to 40 °C.

As standard technology for all Raytec machines, Curiosity features a traction controlled, stabilized belt that reaches the speed of 240 m/min.

Raytec has chosen the best performing optical resolution, 0,3×0,3 mm, to consent the most accurate image understanding.

Benefits

High production capacity

Selection of large quantities of product in little time

Low maintenance

(up to 100% according to the applicaion).

Real-time detection

of qualitative data of raw material analysed

Automatic capture of images

of rejected products and their filing for post-production analysis

Constant selection over time

also over 3 work shifts

Low maintenance costs

User-friendly software

for easy use and programming